What is POU Technology?

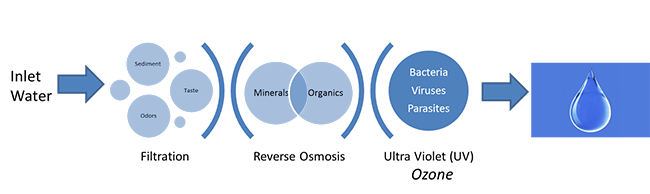

The aggregate of conventional water treatment technologies packaged into a convenient, ergonomic dispense format.

Sediment or particle filtration is the first step of the water purification process. Typically sediment filters of “5 micron” size are used to remove suspended particles 5 micron or greater in size. Water that is cloudy with small particles (turbidity) will come out clear in appearance. However, this phase of the purification process does not remove harmful bacteria and viruses, organic substances present in the water or soften hard water (high alkalinity).

Activated Carbon Filtration

Activated carbon filtration, a form of ultrafiltration – sometimes referred to as carbon block filters - will remove tastes, odors, and low concentrations of organic chemicals (such as pesticides and solvents) from drinking water. Activated carbon will also reduce radon gas and chlorine, the later important for municipal waters treated by a chlorine purification processes. Though some carbon filters can reduce low level amounts of lead, copper and mercury present in municipal waters, they do not reduce major inorganic ions (e.g. sodium, calcium, chloride, nitrate, and fluoride or metals). Activated carbon filters will not soften or disinfect water. The activated carbon filter typically follows the first step (particle filtration) of the purification process. In home and commercial point-of-use systems it is common to use a granulated-activated carbon (GAC) as a final filtration step to “polish” the water before dispense.

Ultraviolet (UV) Treatment

UV treatment is a disinfection method that uses ultraviolet light (short wavelength) to kill microorganisms – such as pathogens, viruses, molds and fungi; it is used in a variety of applications such as food, air and water purification. To effectively disinfect water with UV treatment, the water to be treated must in no way be turbid or cloudy – the water must be pre-treated with sediment and carbon filtration. When properly implemented, UV treatment can destroy 99.99% of germs.

Reverse Osmosis

Reverse Osmosis (RO) is a common point-of-use water treatment method to reduce total dissolved solids (TDS) in drinking water. RO, perhaps best known for use in water desalination projects, can reduce toxic pollutants like arsenic, lead, and many types of organic chemicals. RO treatment is not effective for the removal of dissolved gases such as radon, or for some pesticides and volatile organic chemicals such as solvents. Pretreatment such as particle filtration (to remove sediments), carbon filtration (to remove volatile organic chemicals), disinfection methods – such as chlorination, UV, or ozone – (to disinfect and prevent microbial growth), may be necessary for optimum RO treatment.

Ozone

Ozone (O3) is a naturally occurring (or artificially created by ultraviolet light acting on oxygen) oxidizing agent. As an oxidizing agent, ozone destroys algae, viruses, bacteria, and fungi on contact. Ozone kills microorganisms by rupturing their DNA. Ozone has been used for disinfection of water for over 100 years; currently used in municipal water treatment facilities in Los Angeles, Dallas and Las Vegas and broadly across Europe. Ozone is also commonly used for water disinfection treatment in bottle water and soft drink bottling plants around the world. AguaOzone employs the ozone disinfection properties to sanitize the POU dispenser on a nightly basis. This minimizes the need for periodic equipment sanitization and functions as an added layer of health (equipment!) protection beyond the standard water treatment processes engaged in POU water dispense equipment.